The company relies on a high degree of brand awareness, fine product quality, convergence of multiple strong advertising media power, and through the integration of capital, knowledge, talent technology, channels, information operations.

A Mini Bread Pans Factory plays an essential role in the bakeware industry, offering small-sized baking molds that meet the growing demand for compact, portion-controlled, and artisan-style bread products. These factories must balance craftsmanship and automation to deliver consistent quality and efficiency. As consumer trends shift toward home baking and personalized food portions, the production standards and technological advancements of such factories have become even more critical.

Material Selection and Design Standards

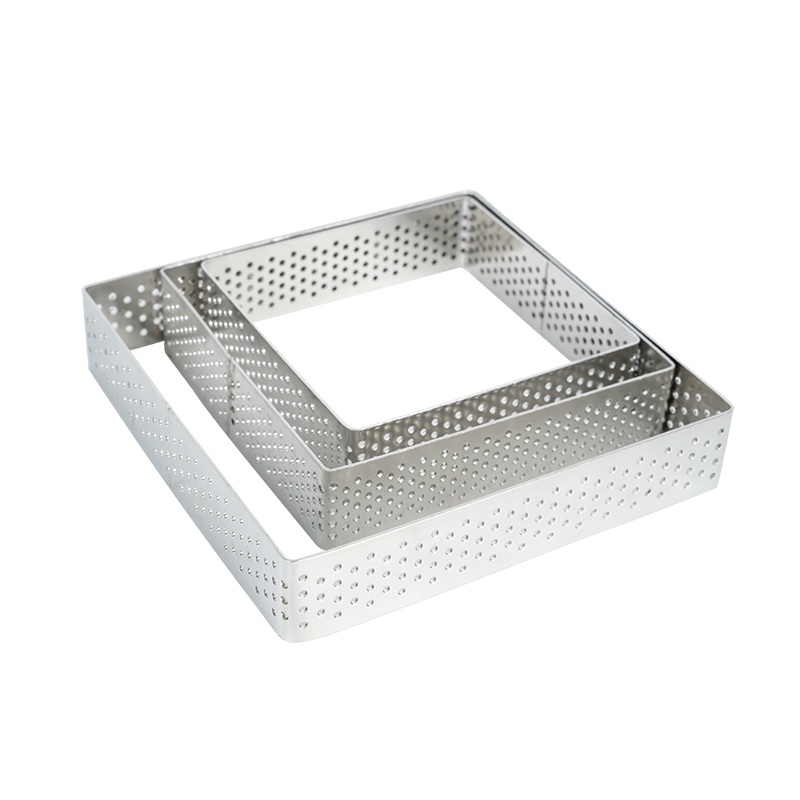

The foundation of quality mini bread pans lies in the choice of materials and design precision.

- Material Choice: Factories often use aluminum, carbon steel, or stainless steel, depending on the product’s intended use and desired heat conductivity. Aluminum offers lightweight handling and even heating, while stainless steel ensures corrosion resistance and durability.

- Design Details: Proper pan design includes reinforced edges, smooth corners, and non-stick coatings to improve structural integrity and ease of release. Factories must also ensure dimensional consistency across batches, maintaining compatibility for industrial and home ovens alike.

Manufacturing Processes and Quality Control

The production process in a Mini Bread Pans Factory involves several crucial stages that define the final product’s quality.

- Molding and Shaping: Precision stamping or extrusion ensures that each pan meets exact thickness and shape requirements.

- Surface Treatment: Non-stick or silicone coatings are applied under controlled temperature conditions to ensure uniform coverage and adherence.

- Inspection: Automated sensors and visual inspection systems detect scratches, dents, or coating inconsistencies before packaging.

By combining mechanical precision with human oversight, the factory ensures reliability and reduces defects to near zero.

Technological Innovations in Production

Modern factories embrace innovation to stay competitive.

- Automation and Robotics: Automated assembly lines reduce labor costs and improve speed without compromising accuracy.

- Smart Monitoring: Sensors track temperature, humidity, and forming pressure, allowing real-time adjustments for consistent production quality.

- Eco-Friendly Initiatives: Many factories now use water-based coatings and energy-efficient ovens to reduce environmental impact, aligning with global sustainability goals.

Customization and Market Adaptability

Customization is a key factor in the success of modern bakeware manufacturing.

- Variety of Sizes: Factories offer multiple pan sizes and shapes to suit bakery chains, restaurants, and home users.

- Branding Options: Some clients request embossed logos or unique surface textures to enhance brand identity.

- Flexible Production: Modular tooling systems enable quick changes between product types, allowing the factory to respond efficiently to shifting market needs.

Challenges in Maintaining Consistency

Despite technological progress, factories face several challenges.

- Coating Uniformity: Achieving even non-stick layers remains complex, especially in high-speed production.

- Material Cost Fluctuations: Rising prices for metals or coatings can pressure profit margins.

- Global Standards: Factories exporting products must comply with varying safety and environmental regulations, requiring strict internal audits and certifications such as ISO or SGS.

Commitment to Customer Satisfaction

To build long-term trust, a Mini Bread Pans Factory must align its operations with customer expectations.

- Durability Testing: Pans undergo repeated heating and cooling cycles to assess longevity.

- User Feedback Integration: Continuous dialogue with bakeries and distributors helps improve design and performance.

- After-Sales Support: Providing replacement parts, maintenance advice, and warranty services strengthens brand reputation and client loyalty.

Balancing Efficiency and Craftsmanship

The success of a mini bread pan manufacturer lies in its ability to combine precision engineering, innovative technologies, and responsive customer service. From material selection to final inspection, every step reflects a commitment to consistency and well. As the market for artisanal and small-batch baking continues to expand, factories that integrate sustainability, adaptability, and quality assurance will remain at the forefront of the global bakeware industry.

English

English русский

русский Español

Español