The company relies on a high degree of brand awareness, fine product quality, convergence of multiple strong advertising media power, and through the integration of capital, knowledge, talent technology, channels, information operations.

The Role of Carbon Steel Bakeware

A Carbon Steel Bakeware Factory is central to the production of professional and household baking tools known for their strength, durability, and even heat distribution. As baking has evolved from a traditional craft into a precision-driven science, the importance of reliable materials has grown significantly. Factories specializing in carbon steel bakeware must integrate advanced metallurgy, surface technology, and quality control to ensure products meet global standards and satisfy both commercial and home bakers.

Material Selection and Metallurgical Foundation

The foundation of any bakeware’s performance lies in the metal itself.

- Composition: Carbon steel contains a balanced ratio of iron and carbon, giving it higher tensile strength than aluminum while maintaining good thermal conductivity.

- Thickness and Density: Factories must carefully regulate sheet thickness—too thin causes warping under high heat, while too thick causes uneven heating and slow temperature response.

- Surface Finish: Polishing or coating prevents rusting and facilitates even baking. The preparation of the raw metal surface is critical to achieving consistent product performance.

Manufacturing Process and Forming Techniques

The production process in a Carbon Steel Bakeware Factory involves several precision stages.

- Cutting and Forming: Automated presses shape sheets into desired molds with exact dimensions. Edge rolling and reinforcement prevent deformation during repeated use.

- Coating Application: Non-stick coatings such as PTFE or ceramic layers are applied through electrostatic spraying or immersion methods to ensure uniform coverage.

- Curing and Heat Treatment: Controlled heating solidifies coatings and relieves stress in the metal, increasing its resistance to cracking or bending during baking cycles.

Surface Technology and Performance Enhancement

To maintain a balance between strength and usability, factories employ advanced surface treatments.

- Non-Stick Innovations: Modern coatings resist scratching, support high temperatures, and provide smooth food release without chemical leaching.

- Anti-Corrosion Layers: Carbon steel’s susceptibility to rust requires precision coating to protect against oxidation in humid or acidic baking environments.

- Color and Aesthetic Options: Factories now integrate color coating systems that improve brand appeal while maintaining heat resistance and safety compliance.

Quality Control and Testing Procedures

Consistent quality is the hallmark of reliable bakeware manufacturing.

- Dimensional Testing: Each pan’s geometry is checked using digital scanners to ensure uniformity.

- Thermal Performance Evaluation: Sample products undergo heat distribution and temperature recovery testing to confirm consistent baking results.

- Durability Assessment: Repeated mechanical stress and coating abrasion tests simulate real-life use conditions to ensure longevity.

Technological Advancements and Automation

Factories continue to evolve through automation and digitalization.

- Smart Production Lines: Automated robots manage forming, coating, and inspection, reducing human error.

- Energy Efficiency: New furnace systems recycle heat, reducing energy consumption while maintaining uniform curing temperatures.

- Digital Monitoring: IoT systems collect and process data, enabling predictive maintenance and reducing downtime.

Environmental and Safety Considerations

Sustainability and safety have become essential to modern production.

- Eco-Friendly Materials: Many facilities are shifting toward water-based coatings and lead-free compounds.

- Waste Reduction: Precision cutting reduces metal waste, and recycling programs return excess material to the production cycle.

- Worker Safety: Ventilation systems and automated handling reduce human exposure to fumes and heat.

Customer-Centric Production and Market Adaptability

To remain competitive, factories must align production capabilities with client needs.

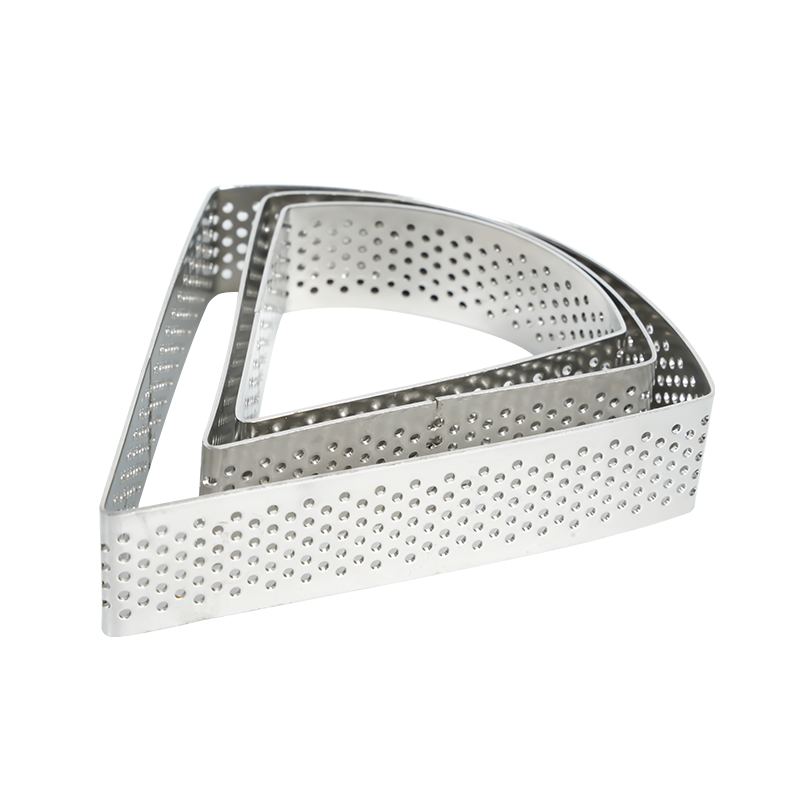

- Customization: Bakeware can be tailored in size, shape, and coating type for different baking sectors, from commercial bakeries to household brands.

- Packaging and Branding: OEM services enable clients to brand their products with custom designs and labeling.

- Global Compliance: Products must meet FDA, LFGB, and EU safety standards before export, ensuring international market acceptance.

Engineering Precision into Every Pan

The continued success of a Carbon Steel Bakeware Factory depends on a combination of technical mastery, material well, and innovation. From the chemical structure of the steel to the final non-stick finish, every detail impacts performance. As automation, sustainability, and customization redefine global manufacturing standards, these factories will remain key players in delivering bakeware that embodies strength, precision, and long-term reliability.

English

English русский

русский Español

Español